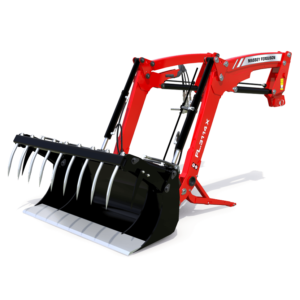

Description

Key Benefits

Exceptional Cutting Capabilities

The MF 2250 has a cutter with 17 knives, whilst the MF 2260, MF 2270 and MF 2270 XD all have 26 knives. The knives are arranged in two banks which can be simply engaged and disengaged from the cab using the C1000 monitor and spool valve. All knives engaged gives a chop length of 43.5mm and with a single knife-bank engaged 87mm.

Pre-Compression System

Massive capacity, industry leading bale density and superb shape all stem from the award winning pre-compression chamber design. Only when the chamber is perfectly full will the trip door activate and the stuffer fork powers the fully formed flake into the bale chamber.

The heaviest and strongest plunger in the industry

Driven by an enormous gearbox with massive strength, the plunger is connected via two heavy duty connecting rods. Contained in these are load cells that measure the load on the plunger face. Information from the load cells is used to control the automatic density control system and also provides the operator with driving arrow guides if uneven swaths are encountered.

OptiFormᵀᴹ bale chamber

The bale chamber on the MF 2200 Series is engineered to produce bales with perfect shape and incredible density. Its design will give massive strength and year after year of reliability. The MF 2270 XD and the MF 2290 baler feature the OptiForm bale chamber, which ensures ‘Optimal Formation’ of the bale on these high capacity and high density models.

Double-knotter system

The double-knotter system pioneered at the Hesston factory has an unrivalled record of reliability, tying many millions of bales all over the world for over 40 years. It continues to perform this vital role in the MF 2200 Series balers.